Mercedes pearl effect paint, renowned for its vibrant, iridescent finish caused by micro-metallic particles, is both durable and delicate. Environmental factors like temperature, humidity, air pollution, and everyday wear can damage the finish, requiring regular maintenance including washing, waxing, and Mercedes pearl effect repair services to preserve its beauty and longevity. Paintless dent repair (PDR) is suitable for minor imperfections, while adhering to pH-neutral cleaning and high-quality waxing practices is key to maintaining the intricate pearl effect.

Mercedes Pearl Effect paint, renowned for its stunning iridescent finish, has become synonymous with luxury automobiles. However, the environmental impact on this intricate composition is a growing concern. This article explores the delicate balance between nature and automotive aesthetics, focusing on understanding the unique make-up of Mercedes Pearl Effect paint and how environmental factors influence its quality and longevity. We also delve into strategies for effective Mercedes pearl effect repair and maintenance.

- Understanding Mercedes Pearl Effect Paint Composition

- Environmental Factors Affecting Paint Quality and Durability

- Strategies for Pearl Effect Repair and Maintenance

Understanding Mercedes Pearl Effect Paint Composition

Mercedes Pearl Effect paint is renowned for its stunning, iridescent finish—a result of a complex composition that combines traditional pigmented paints with advanced micro-metallic particles. This unique blend creates a dynamic visual effect, reflecting light in captivating ways. The intricate structure involves fine metal flakes embedded within the paint layer, providing depth and lustre. This innovative design is not merely cosmetic; it also serves to enhance durability, offering superior protection against chipping and fading compared to conventional paints.

While the aesthetics are undoubtedly a draw, this specialized paint is delicate, making it particularly susceptible to damage from environmental factors. A fender bender or minor collision can disrupt the intricate layers, leading to imperfections visible under certain lighting conditions. As such, understanding these environmental impacts is key when considering Mercedes pearl effect repair and auto body services. Proper care, including regular washing and waxing, can help maintain the paint’s integrity, ensuring its captivating effects endure for years to come.

Environmental Factors Affecting Paint Quality and Durability

Various environmental factors play a significant role in determining the quality and durability of Mercedes pearl effect paintwork. Firstly, temperature and humidity levels during application and curing can impact the paint’s adhesion and overall finish. Extreme heat or moisture may cause the paint to dry too quickly, leading to bubbles, runs, or an uneven surface. Conversely, low temperatures can slow down drying, potentially causing the paint to become tacky for longer periods, increasing the risk of smudging or damage during handling.

Additionally, air pollution and exposure to various atmospheric contaminants can degrade the paint’s resilience over time. Particulate matter, volatile organic compounds (VOCs), and ultraviolet (UV) radiation from sunlight can all contribute to premature fading, chipping, or cracking. Regular auto repair services that include washing and waxing can help mitigate these effects, preserving the pearl effect finish of Mercedes vehicles for longer periods. Auto painting experts are well-equipped to handle bumper repair and other paint-related issues, ensuring a vehicle’s aesthetic appeal remains intact even after exposure to such environmental challenges.

Strategies for Pearl Effect Repair and Maintenance

Mercedes pearl effect paint is renowned for its captivating, iridescent finish—a result of intricate micro-particles embedded within the coat. However, this delicate beauty is susceptible to damage from environmental factors and everyday wear and tear. Scuffs, scratches, or even a minor fender bender can disrupt the uniform glow, leading to a less-than-ideal appearance. Fortunately, strategies for Mercedes pearl effect repair and maintenance exist to restore and preserve this distinctive finish.

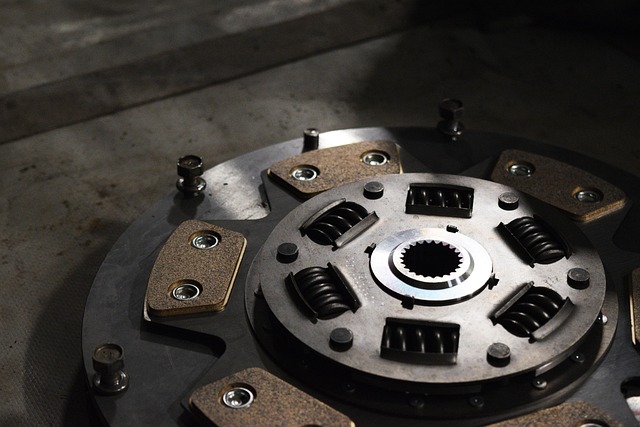

One effective approach is paintless dent repair (PDR), which involves using specialized tools to gently work out dents and scratches on the surface without disturbing the paint. This method is ideal for minor impacts, like a fender bender or a door ding, as it leaves no visible repair marks. Regular washing and waxing also play a crucial role in maintaining pearl effect paint quality. Using pH-neutral cleaners ensures that the intricate micro-structure of the finish remains intact, while applying top-quality wax provides an extra layer of protection against environmental contaminants like dust and UV rays.

The intricate beauty of Mercedes’ Pearl Effect paint is a result of a sophisticated composition designed to withstand environmental challenges. By understanding the interplay between these elements, we can better appreciate and maintain this distinctive finish. Environmental factors, from UV exposure to humidity, significantly impact paint quality and durability, necessitating specific strategies for repair and maintenance, especially when it comes to Mercedes pearl effect repairs. Implementing these practices ensures that the glossy, multifaceted allure of Pearl Effect remains intact, preserving the vehicle’s aesthetic appeal for years to come.