Mercedes pearl effect repair is a specialized process celebrated for its dazzling finish on high-end vehicles. Skilled technicians use multi-stage coatings and precise alignment to achieve an iconic, iridescent look, vital for fleet repairs and classic car restorations. This meticulous art ensures a seamless, durable result, mimicking natural pearls' radiant allure.

“Discover the art of restoring Mercedes pearl effect finishes with our comprehensive guide. Mercedes pearl effect coatings are renowned for their exquisite, iridescent glow, demanding meticulous care in repairs. This article delves into the intricate world of these coatings, explaining their multi-stage application process and highlighting techniques for achieving perfect matches. Whether you’re a professional or enthusiast, understanding how to master Mercedes pearl effect repair is essential for preserving the car’s vibrant, unique finish.”

- Understanding Mercedes Pearl Effect Coatings

- Multi-Stage Coating Process Explained

- Achieving Perfect Matches in Repairs

Understanding Mercedes Pearl Effect Coatings

Mercedes pearl effect coatings are renowned for their stunning, iridescent finish—a signature look that adorns many high-end vehicles, including Mercedes-Benz models. This unique coating technology creates a multifaceted, shimmering effect that catches the light beautifully, revealing layers of color and depth. At its core, a Mercedes pearl effect repair involves meticulous application of specialized multi-stage coatings designed to mimic this signature aesthetic.

Understanding the intricate structure of these coatings is key to achieving a successful repair. Each stage builds upon the previous one, requiring precise matching to ensure the final result aligns perfectly with the original factory finish. This involves careful color analysis and texture matching, as well as an in-depth knowledge of car body restoration techniques specific to Mercedes benz repair. Reputable car bodywork services will employ trained professionals who can navigate this process, ensuring a seamless and visually striking pearl effect on restored vehicles.

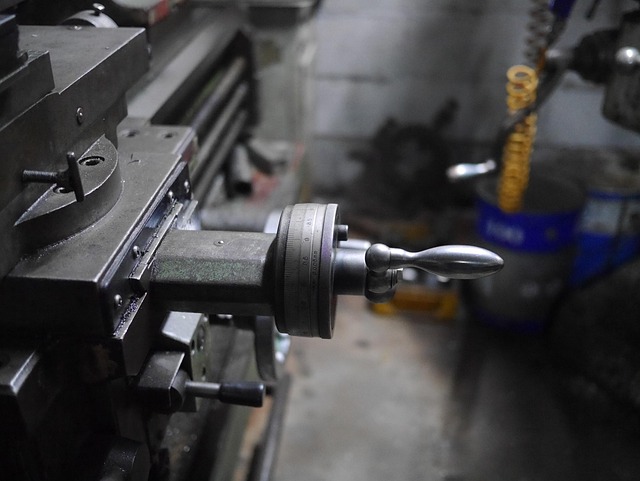

Multi-Stage Coating Process Explained

The multi-stage coating process is a meticulous art crucial for achieving the iconic Mercedes pearl effect repair. It involves several layers of specialized coatings designed to mimic the radiant, iridescent look of natural pearls. The journey begins with a base coat that sets the tone and color palette for the subsequent layers. This initial step is vital for creating a smooth canvas, ensuring the final effect is flawless.

As the process advances, additional coatings are meticulously applied, each adding depth and luster. These coatings often include unique formulations tailored to enhance specific visual aspects like light reflection and refraction, resulting in the breathtaking, 3D-like appearance associated with pearl effects. The expertise of skilled technicians is essential here, as they must ensure precise application and perfect alignment for a seamless finish, especially in fleet repair services or automotive body work involving vehicle restoration.

Achieving Perfect Matches in Repairs

In Mercedes pearl effect repairs, achieving perfect matches is an art that combines precision and expertise. To ensure a seamless finish, technicians must carefully select multi-stage coatings designed to replicate the precise shade and texture of the original pearl effect. This meticulous process involves not just matching the color but also duplicating the unique iridescent effect that makes these finishes so captivating.

Whether it’s for a classic car restoration or modern vehicle repair services, frame straightening plays a crucial role in preparing the surface before application. By eliminating any imperfections and ensuring a smooth base, technicians can guarantee that the multi-stage coatings adhere perfectly, resulting in a durable and visually stunning pearl effect repair.

In conclusion, mastering the art of Mercedes pearl effect repair involves understanding the intricate multi-stage coating process and its critical role in achieving perfect matches. By delving into these techniques, professionals can ensure that repairs not only restore but enhance the iconic Mercedes pearl effect, maintaining the vehicle’s distinctive allure and value.